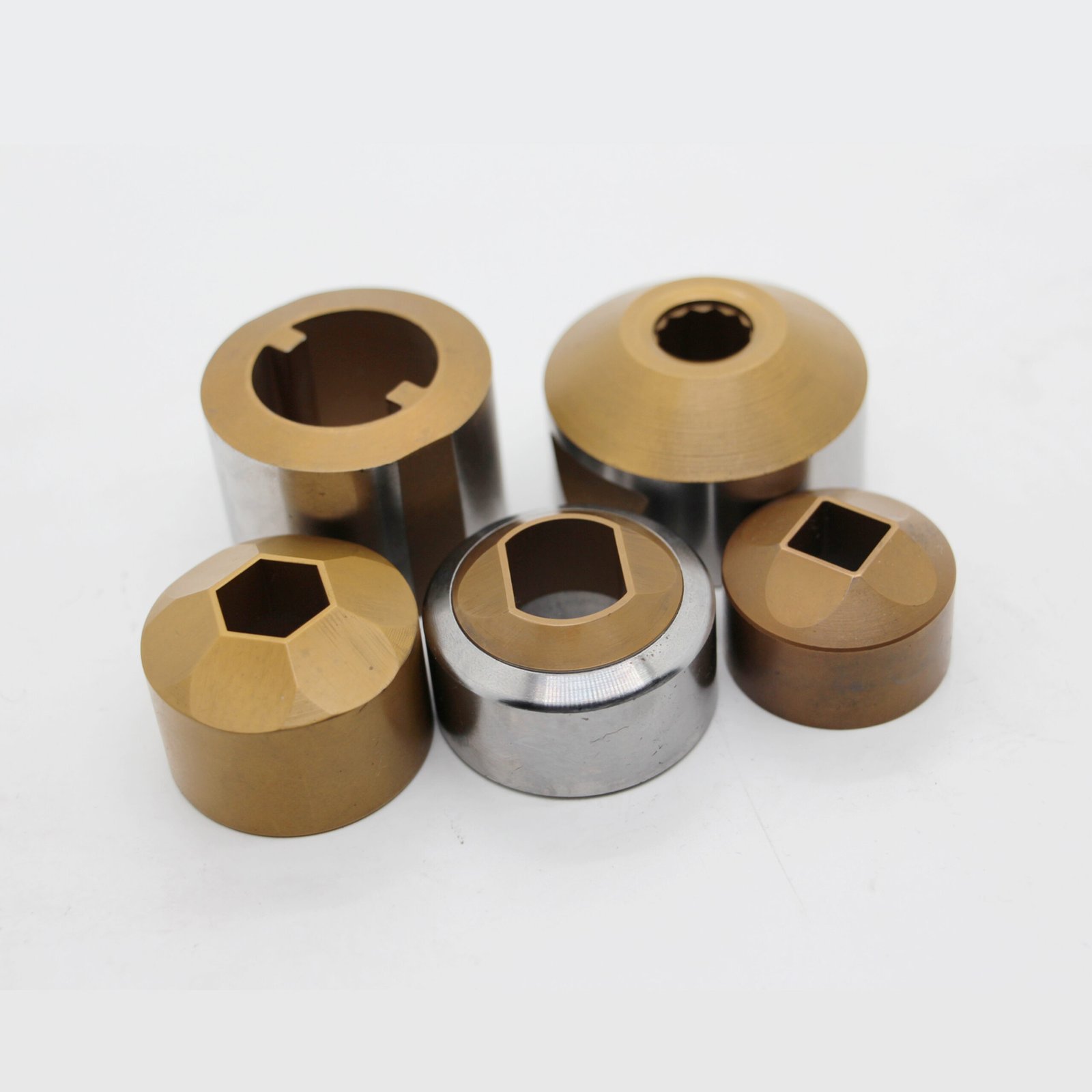

Precision Custom Cold Heading Dies – Unmatched Accuracy for Your Success

Whether you’re a craftsman, manufacturer, or hobbyist, precision is paramount to your project’s success. Our custom cold heading dies are engineered to meet your exact specifications, ensuring every detail perfectly aligns with your requirements. Manufactured with premium materials and innovative techniques, these dies deliver exceptional reliability, durability, and performance across all applications.

Built to Your Exact Specifications

We understand every project is unique. That’s why we manufacture fully customized cold heading dies based on your technical drawings. You maintain complete control over the design process—from dimensions and geometry to complex details. Our expert team guarantees each die meets your precise needs. Simply share your drawings, and we’ll handle the rest with advanced manufacturing technologies and master craftsmanship to exceed expectations.

Versatile Solutions for Diverse Applications

Our product range extends beyond standard designs. We offer multiple configurations tailored for various industries—whether you need dies for high-strength fasteners, automotive components, aerospace parts, or specialized hardware. No matter the complexity, our custom cold heading dies provide the versatility and quality to ensure first-time-right production.

Why Choose Our Custom Cold Heading Dies?

When you choose our dies, you’re investing in more than tooling—you’re securing peace of mind. Each die undergoes rigorous testing for:

-

Structural integrity under extreme pressures

-

Micron-level forming accuracy

-

Long-term wear resistance

With bespoke engineering, uncompromising quality, and exceptional customer support, our cold heading dies have become the trusted choice for global manufacturers and innovators.

Eliminate tooling compromises—invest in custom cold heading dies that perfectly match your vision. Experience the craftsmanship, quality, and customer-first approach we build into every order.

Reviews

There are no reviews yet.