Achieve Exceptional Quality with Precision Custom Thread Rolling Dies

When it comes to manufacturing solutions, quality, reliability, and precision are key. Our Precision Custom Thread Rolling Dies are engineered to elevate your production capabilities. Built with expert craftsmanship and cutting-edge technology, these thread rolling dies offer unparalleled performance for a variety of industrial applications. If you’re in search of solutions that optimize efficiency while delivering consistent, high-quality results, you’ve come to the right place.

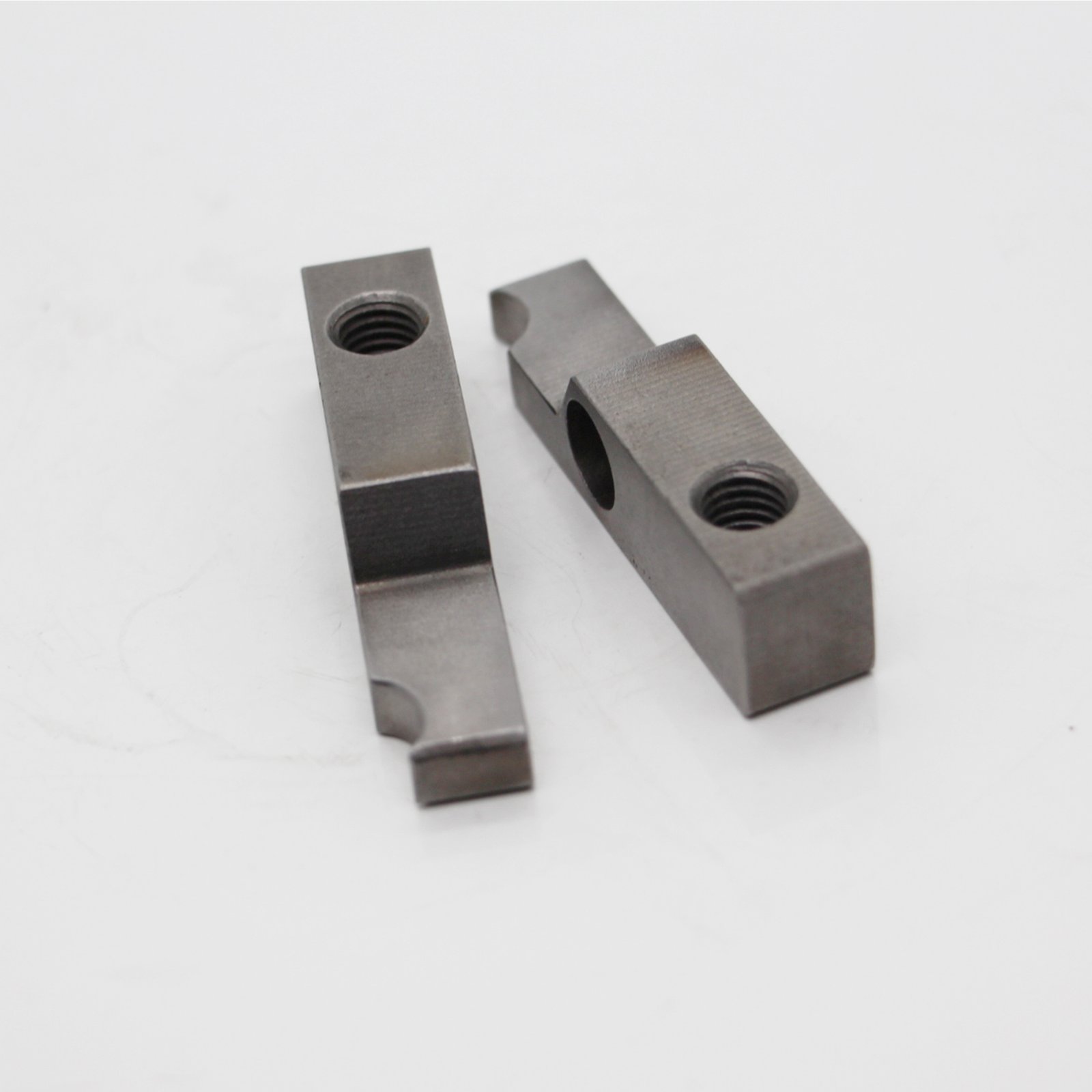

Designed for Maximum Durability and Versatility

Our thread rolling dies are meticulously designed to withstand the rigors of high-speed production environments. Manufactured using premium-grade materials, they offer remarkable wear resistance and extended lifespan, minimizing the need for frequent replacements. Whether you’re working with aluminum, stainless steel, or titanium, these dies are versatile enough to handle a wide range of materials. From small batches to large-scale manufacturing, they adapt seamlessly to meet your unique production demands.

Engineered Precision for Superior Thread Quality

The core of our Precision Custom Thread Rolling Dies lies in their engineering. Each die is precision-machined to ensure exact thread profiles with minimal variability. The result? Perfectly formed threads that enhance the mechanical properties of your components, including improved strength and fatigue resistance. Whether your application involves threading screws, studs, or other intricate components, these dies consistently deliver excellence.

Partner with Us for Tailored Solutions

We understand that no two production lines are the same. That’s why we are committed to creating custom solutions tailored to your specific needs. Our team will collaborate with you to design and manufacture thread rolling dies that align perfectly with your application requirements, ensuring both compatibility and optimal performance.

Why Choose Our Thread Rolling Dies?

Choosing the right tools for your manufacturing process can make all the difference. Here’s why our Precision Custom Thread Rolling Dies stand out:

- Exceptional durability and long service life

- Accurate thread profiles for superior performance

- Custom-designed solutions tailored to your needs

- Versatility for a wide range of materials and applications

- Industry-leading customer support and technical expertise

Investing in our thread rolling dies means investing in quality, efficiency, and reliability. Experience the difference that precision engineering can bring to your production process.

Reviews

There are no reviews yet.